There is no denying that despite significant time and effort spent by general contractors (GCs) and their partners, construction projects of all sizes are troubled by escalating cost-overruns and waste caused by quality issues. Installation errors are caught late and based on spot checks, usually when the next subcontractor comes in, or even worse, when projects are handed over and the cost of fixing errors is 10X higher!!!

Poor installation quality and associated rework are estimated to cost the global $12 trillion construction industry around 12% every year, resulting in a $1 trillion crisis of lost productivity and margins. This doesn’t even take into consideration the time and effort required to verify the quality of installed work, which adds up to 3% of total project costs on top of immediate rework cost; nor does it include the significant waste, CO2 emissions and reputational damages involved.

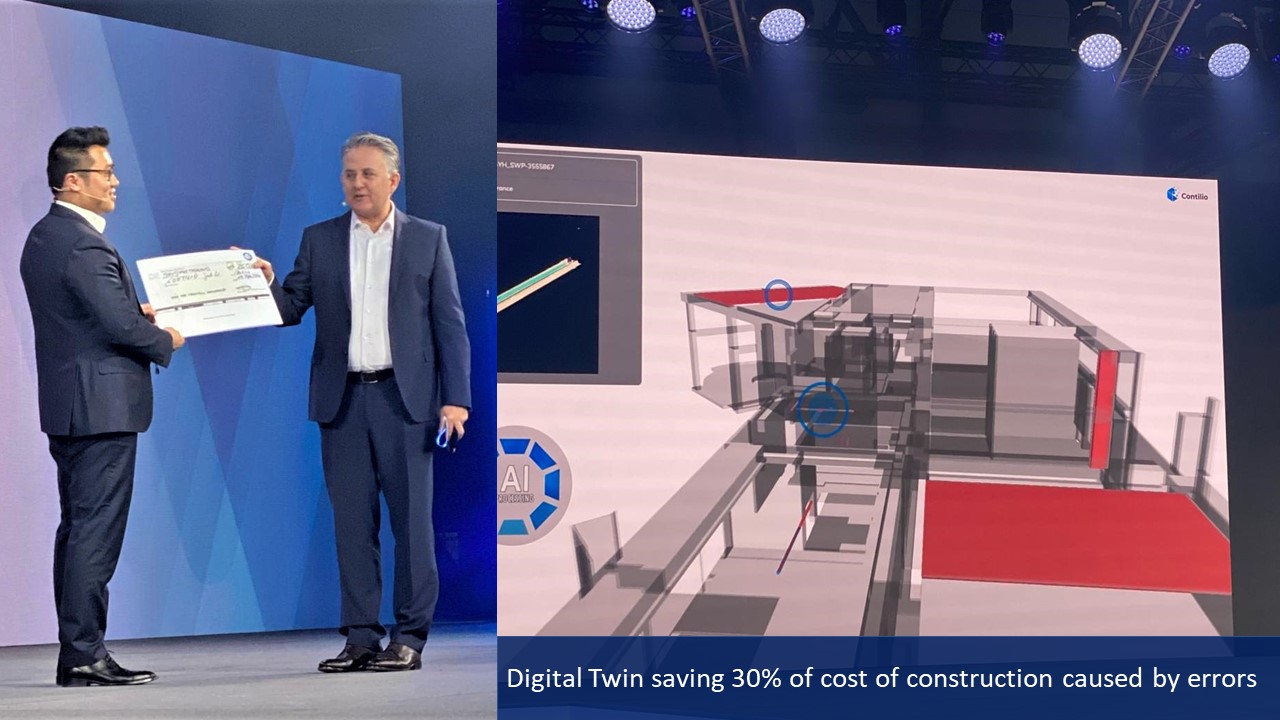

As an industry we’ve tried to fix this problem by pouring more people at the problem and transferring the risks, but progress has been limited. We interviewed several experts and stakeholders in the industry and identified 5 key trends that will increase construction complexity and make things worse. But, we have also identified best practices used by industry leaders to turn these challenges into cost savings, enhanced build quality and sustainability measures, using the latest technologies. For a more in-depth example on how one of our global customers achieved 30% lower rework costs and 23% higher productivity for the construction of their new APAC Headquarters using the Contilio 3D AI analytics software, please read this case study here.

The current process: manual, limited outcomes, and little trust

|

“Normally, the responsibility for construction quality lies with the subcontractors, but there is so little trust and so much complexity that the main contractor ends up doing much of the quality inspection themselves, adding significantly to the project costs and overhead.”

Project Director, Bouygues Construction

|

Today, the process to verify and manage installation quality is very time consuming, slow and it involves many people who need to be on site. As different trades and subcontractors complete different parts of the construction, the GCs try to verify the quality of installed work through spot checks and then manually update documents and systems spread across different “data siloes”. Construction managers, work package managers, quality engineers, and commercial teams all spend significant portion of their time on ensure quality, adding 1%-3% to the project costs just to inspect work. And despite all these efforts, teams report that at most they can check 5% of the work installed, leaving the remaining 95% up to chance, built-in contingencies and warranty packages.

In addition, quality KPIs such as number of critical defects, the time and cost to fix them, and their impact on the delivery speed are usually not tracked using a standardized, scalable process. Subjective and delayed outputs end up in various data siloes, without being meaningfully used to drive efficiencies.

While contractually the subcontractors might be responsible to track and report on installation quality, in reality, the GCs whose commercial success and reputation are closely tied to long-term asset quality and successful construction delivery end up verifying all the work done by trades! Equally if you are an asset owner or an investor, you want to ensure that the asset you ordered is what is getting built and the quality issues are identified and resolved immediately. If you are a public sector entity, you want to maximize value for taxpayers, achieve your sustainability outcomes and ensure fair payment and transparency. We live in a world where data-backed quality assurance is becoming increasing important, particularly when several trades/subs are onsite simultaneously (when MPE and services are getting installed).

This trend is only going to accelerate at a much faster pace

As a part of Contilio’s growing engagement with the global construction industry, we interviewed the executive and delivery teams from several construction companies on the pressing matter of build quality and identified five key trends making the construction quality and sustainability challenge even more daunting:

1. COVID-19 has made manual, on-site quality verification hard: Many construction companies are forced to reduce the number of onsite crew due to COVID-19 safety requirements, but at the same time still have to track and document installation quality reliably particular for critical assets such as healthcare facilities, data centres, and technology assets. With increasing pressure to offset the pandemic’s negative impact, this is only going to get harder. Digital leaders are turning to automated software solutions that can help verify quality of all elements in a few hours, improving productivity and safety simultaneously.

2. The labour gap is widening: Young expert and young talent is less and less interested in moving around the construction sites and “ticking boxes” to manually verify the onsite quality. They want to focus on high-value tasks and conduct their work supported by digital tools, just like what they would do in other industries. We strongly believe that digitization and adoption of the latest available AI technologies can reverse this trend and increase the construction industry attractiveness as an employer. It can also enable your expert workforce to focus their efforts on what matters the most.

3. Good subcontractors have less incentive to focus on quality: Good subs are in high demand and want to finish their jobs quickly and move to the next one to maximize their utilization. This, together with increasing delivery complexity and trend #2, makes installation quality verification and rework even costlier – something we believe our cutting-edge and easy to use solution can help address.

4. Offsite manufacturing needs verification too! Yes, offsite and modular are picking up fast and the great news is that they have the potential to drive significant efficiencies – but similar to manufacturing, the installation quality (i.e. dimensions and fit to the rest of the site) needs to be verified to mm accuracy before the components are shipped to the site; otherwise, everyone ends up paying significantly more for rework, logistics, and other costs.

5. 360 photos and videos are no “silver bullet”: While the industry has seen a few 360-degree photo tools used more broadly for site visualization, construction companies have already realized that photo-based solutions cannot be relied upon to check the installation quality automatically, whatever the marketing message. Only AI solutions that work with 3D data can offer the accuracy and the automation potential to do so.

|

“We have tested some photo-based solutions to visualize our sites, but we would never rely on photos to evaluate quality of subs work or for disputes, as photos do not tell the full story”

Head of Quality Inspection, Sir Robert Mcalpine

|

The opportunity for Digital Leaders in construction

But it is definitely not all doom and gloom. Several construction companies have started to test and deploy software solutions at scale to address the big quality challenge and drive a long overdue digital transformation. Besides the mitigations for trends mentioned above, Digital Leaders are additionally:

1. Establishing new digital records of transparency and trust: Digital leaders are using software tools and technology solutions to create traceable, structured and trustworthy digital records and quality insights for 100% of installed work as opposed to the traditional 5%. and they do it in just a few hours. This new transparency establishes a “single source of trust”, from which the general contractors, the subcontractors and the owners benefit alike.

2. Using analytics to finally drive cross-portfolio efficiencies: Yes, you got that right. Enabled by the latest advancements in AI and analytics, digital leaders can leverage actionable insights captured on one project and use it in real-time across their entire portfolio to predict and avoid similar installation mistakes, saving additional costs. They can also use these insights to win more tenders, and/or to drive sustainability benefits in addition to benchmarking assets globally.

3. Not settling for just a “quick digital fix”: Digital leaders do not just choose the cheapest digital tool, but rather systematically assess and embrace digital solution(s) that have the potential to drive tangible value at scale and won’t need to be replaced in a couple years again. And the good news is that advancements in 3D Artificial Intelligence (3D AI), BIM and big data combined with the power of innovative data capture solutions have enabled them to do so effectively.

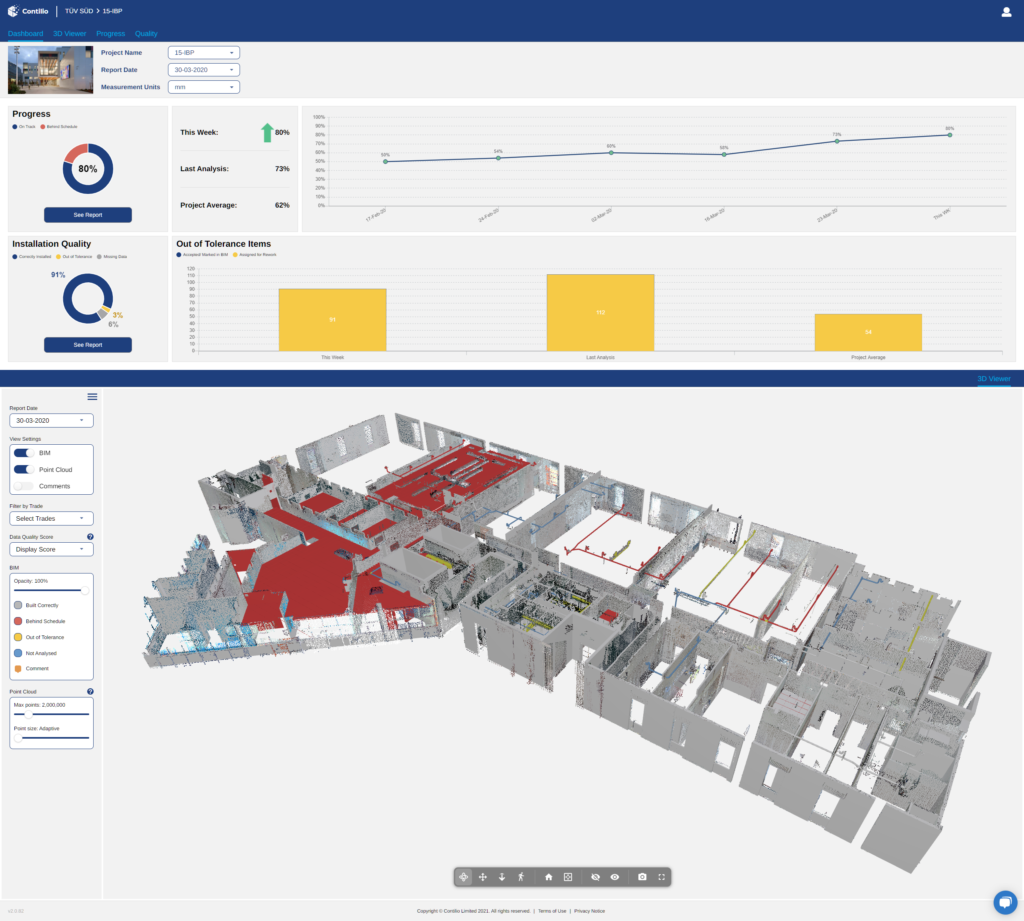

How a global leader reduced rework by 30% using Contilio 3D AI

Based on decades of experience in the construction industry (yes we’ve been in the trenches) and engineering advanced technologies, we developed our cutting-edge and easy to use Contilio 3D AI analytics platform to provide objective, real-time, and fully automated quality verification for all areas of your building and infrastructure projects ranging from millions to a few billions. Drawing on the latest developments in big data analytics, autonomous driving and 3D reality capture, the Contilio 3D AI platform not only can do this in a fraction of a time and cost, and for all trades, but also, we can create machine-readable, structured digital twins (BIM connected with intelligent, structured site data) to enable additional whole-life asset efficiencies.

We are trusted by many GCs and asset owners around the world to verify installation quality and track construction progress, enabling our customers to do a lot more with a lot less, win more business, and ensure they are doing so safely and sustainably. One global customer we’ve been working with deployed Contilio’s 3D AI solution on their new Asia-Pacific Headquarters to verify the quality of 100% of installed work and to reduce the rework costs by 30%. They also experienced significant productivity gains due to significantly reduced need for travel and overhead, augmenting their construction managers and skilled professionals to focus on more value-add activities. See the case study here.

Please get in touch if you’d like to learn how we can join forces to drive significant value for you and construction projects.

Zara Riahi

Chief Executive Officer, Contilio

Email: contilio.official@contilio.com

Phone: +44 7523 746 824

Video: Contilio in 2 mins

Demo: Please click here to book a demo

For marketing and PR please contact Jack Li at jack@contilio.com.

Q5: What is Apple LiDAR then?

Q5: What is Apple LiDAR then?